Connecting in Real-Time with the Moon, 380,000 km Away

Muromachi: Last time, we talked about joining lunar development as our first goal. Let’s now discuss how Honda’s technology can be utilized there.

First off, the Moon is a place where people can’t easily go. The radiation environment is harsh, and even with space suits, the exposure levels are high, which limits how long astronauts can stay.

Including the Apollo era, the total time astronauts have spent working on the lunar surface is only about 80 hours.

Takezawa: Only 80 hours? After all these decades? That’s it?

Muromachi: Exactly. There have been cases where problems arose during operations. Even simple equipment setups took more time than expected, pushing tasks past the daily work limit and forcing them to be carried over to the next day.

That’s why the Moon is just too harsh for humans to work effectively.

Takezawa: Then obviously, it’s time for robots. Machines that can work in place of humans. You just can’t build structures or bases on the Moon without robotic assistance.

Muromachi: That’s exactly where we are now — the very beginning. There’s a shortage of manpower, and humans can’t work in such conditions unaided. Robotics exists to bridge that gap.

What we’re working on now includes both the robot itself and its remote-control systems. In space’s extreme environment, we have to deal with heat, vacuum, and radiation.

We can somewhat leverage car development technologies for heat and vacuum, but radiation is uncharted territory for us. That’s a new frontier we must tackle.

Takezawa: That covers the hardware side. What about software?

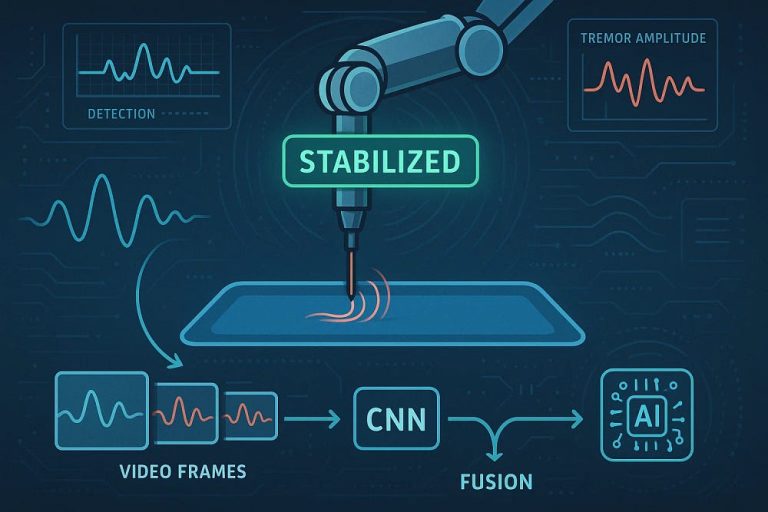

Muromachi: The basic control software isn’t all that different from what we use on Earth. But the avatar-type robot we’re developing is remotely operated via a head-mounted display, which makes you feel like you’re inside the robot — and that turns out to be surprisingly hard.

It’s much easier to control it like a radio-controlled car from the outside, but in space, you can’t just set up external cameras. It’s not a place people can easily reach.

Takezawa: Which is why it’s difficult.

Muromachi: Exactly. That’s where we’re trying to supplement with AI — developing systems that support decisions about what should be automated and what should be manually controlled.

Another major challenge is communication delay. The Moon is 380,000 kilometers from Earth, so even at light speed, there’s a one-way delay of about 1.3 to 1.5 seconds — more than 3 seconds round-trip.

Takezawa: So when we tell a robot to move, it takes about five seconds for us to see what actually happened.

Muromachi: Exactly. That makes real-time operation nearly impossible. We have to automate part of the process.

Our system can still manage delays of about five seconds, maybe even ten.

But when you’re talking about Mars, which is over 100 times farther away than the Moon, delays can be as long as 20 minutes. That means full autonomy is a must — robots have to be able to make their own decisions.

*For reference, NASA’s Mars rover Curiosity communicates once or twice a day during Martian daylight hours. Depending on the distance between Earth and Mars, there can be a one-way delay of 5 to 20 minutes, with up to 40 minutes of round-trip lag.

Takezawa: Which means, the farther the destination, the more valuable our technology becomes. In that sense, maybe Mars isn’t just a dream.

Muromachi: To make that happen, we need robots that can think and act like humans. They don’t exist yet, but with embodied AI and other new technologies, I believe we’ll get there someday.

That’s why the work we’re doing now will definitely lead us into the future.

Takezawa: Let me offer a slightly different perspective. Honda has been investing in robotics technology for 30 or 40 years now. But I think it’s been extremely difficult to find a true “real-world outlet” where that technology can be fully utilized.

Engineers have long struggled with the desire to bring their creations into the world.

Muromachi: Even on Earth, there are very few robots that have succeeded in B2C markets. People often say that robotic vacuum cleaners are practically the only real success story.

Takezawa: And that’s exactly why this is a chance. Because the technical bar is so high, it’s the perfect opportunity for Honda to make use of all the serious investments we’ve made over the years.

We’re finally at a stage where those technologies might actually blossom. That’s the real significance behind bringing robotics into space.

Of course, that’s a lot of pressure on you, Mr. Muromachi. (laughs)

Testing Begins Aboard the International Space Station

Muromachi: One of the initiatives your team is working on is the recently announced test aboard the International Space Station (ISS), right?

Takezawa: Currently, Honda’s space development efforts are built on three main pillars: robotics, rocket technology research, and a regenerative fuel cell (RFC) system that utilizes hydrogen technology.

Among these, the RFC-related technology is the one we’ve announced for testing on the ISS. It’s one of Honda’s most advanced and forward-running projects.

The Japanese team developing hydrogen technology has been leading the effort, while my American team members are working alongside them.

Muromachi: Testing something on the ISS sounds amazing to the public, but in the space industry, it’s actually considered a standard proving ground.

Takezawa: While it’s used routinely for validation in the industry, we at Honda see this as our “first milestone.”

If we truly aim to use our technology in space, then having the record of “it was tested in space” is essential.

Simply put, you can’t claim something is usable in space if you’ve never actually sent it there. It just wouldn’t be convincing.

Muromachi: It’s like saying, “I’ve never built a car, but I’ll sell you one.” No one would buy that.

Takezawa: Yes, testing on the ISS is an important step — but it’s just that, a step along the way.

What we’re aiming for is a state where robots are routinely used in space and are genuinely helping people.

We still have a long road ahead before we get there.

Muromachi: Ultimately, I believe the real goal is for our technology to be actively used in the field. Unless that happens, we can’t say it’s truly meaningful.

Takezawa: Of course, it’s great to achieve proof-of-concept in the early stages. But if we stop there, that’s not what Honda stands for.

As a private company, we’re committed to going all the way — to the point where our efforts actually help people.

Muromachi: Sure, having your own technology tested in space is exciting, but getting carried away with that isn’t right either.

We want to position this ISS demonstration as a proper step toward something greater.

Takezawa: In the space industry, we define outcomes in stages: “minimum success,” “full success,” and “extra success.”

For this ISS test, a major focus is how we ensure safety while humans are involved. It’s also a learning opportunity for everything from safety protocols to launch procedures.

That said, we’re still far from the phase we truly aim for — where our work actually helps people.

I really hope we can get there soon.

Muromachi: Honestly, using robots in human-involved space environments is far more difficult than one might imagine.

But that’s exactly why it’s rewarding as an engineer. And it’s also a fitting stage to test the capabilities Honda has built up over time.

Taking the First Step into an Unseen Future

Takezawa: To be honest, we don’t have a complete roadmap laid out all the way to 2030.

Lunar development itself has only just started moving again after decades of dormancy, and no one can say for sure what lies ahead.

But that doesn’t mean we should just do nothing.

Even if we have to feel our way through it, we have to take that first step and then make decisions based on the view that unfolds.

Muromachi: From an engineering standpoint, I don’t think we need superhero-level robots right from the start.

For early-stage infrastructure work, even relatively simple avatar robots that can handle basic tasks should suffice.

Then, when situations arise that require more dexterous or human-like actions, we can upgrade the technology accordingly.

I think a phased approach like that is the most realistic.

Takezawa: That part is very clear to me. Technically, I feel like “if we try, we can do it.”

But the real challenge lies beyond that — whether we can shape this into something that’s genuinely useful as a business.

Muromachi: We can build a robot that moves. But whether that robot is actually useful is a completely different matter.

Takezawa: Exactly. That’s why, as someone connecting technology to society, I feel I need to define more clearly — in higher resolution — where, for whom, and how it can be used.

Muromachi: Even if an engineer confidently says, “This will be useful!”, you might come back and say, “Do we really need that, though?” (laughs)

But I think that’s a healthy relationship.

+ There are no comments

Add yours